Cast Steel Swing Check Valves

SPECIAL CONSRTRUCTIONS:

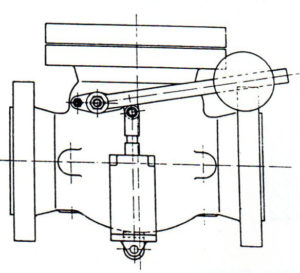

A) OUTSIDE LEVER AND WEIGHT:

On request swing check valves can be furnished with an outside lever and weight. The object of

the lever and weight is either to balance the disc or give it added weight. In balancing the disc

the valve will open with a minimum of pressure. When the disc is weighted the valve will be very

sensitive to a reversal of flow.

B) DASHPOT FEATURE:

In case of intermittent use or in presence of truth dashpot feature is highly recommended. In

such instance the dashpot feature gradually causes the opening and closing of disc preventing

therefore dangerous shocks.

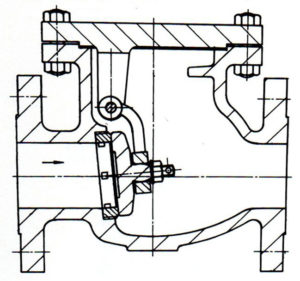

Swing check Valves are used to prevent flow reversal in piping systems. They are suitable for service in

Horizontal or Vertical (flow up through valve only) piping runs. Swing check valves have low pressure

drop and are best suited for moderate velocity applications.

Body:

Its spherical form of radius allows for the stresses, turbulence and resistance to flow to be kept to a

minimum.

COMMON FEATURES:

BODY-BONNET JOINTS:

Body Bonnet joints of check valves are machined as follows:

On 150 and 300 Classes: male and female,

On 600,900 and 1500 Classes: RTJ

SEAT RINGS:

Seat rings are manufactured in two different ways,

depending on the class and type of valves:

1. Screwed seat rings, bottom seated type lapped on both sides.

They are dry assembled, with a controlled torque setting to the body.

2. Wielded-in seated rings, designed in order to prevent any turbulence

and avoid damages due to corrosion.

Both are forged or rolled in one piece, for all dimensions. They are heat treated to obtain the

requested surface hardness and are perfectly cleaned before assembling.

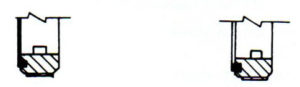

INSERT SEAT RINGS:

These rings are manufactured with Teflon or Viton inserts depending on fluid and service conditions.

They provide an elastometer primary seal, combined with a fire safe metal-to-metal secondary seal for

temperatures from -100 degree Celsius (-144 degree Ferenhiet) to 204.4 degree celcius(400degree

ferenheit). (fig A).

Where maintenance is a potential problem the Viton insert is in the form of a toroidal ring so that it can

be easily removed. (Fig B).